Building service valves are essential components in plumbing and HVAC systems, ensuring efficient control and regulation of fluids within buildings. Choosing the right valve for your project can significantly impact performance, cost, and durability. This guide explores the key types of building service valves, their applications, and factors to consider when making your selection.

Understanding the Different Types of Building Service Valves

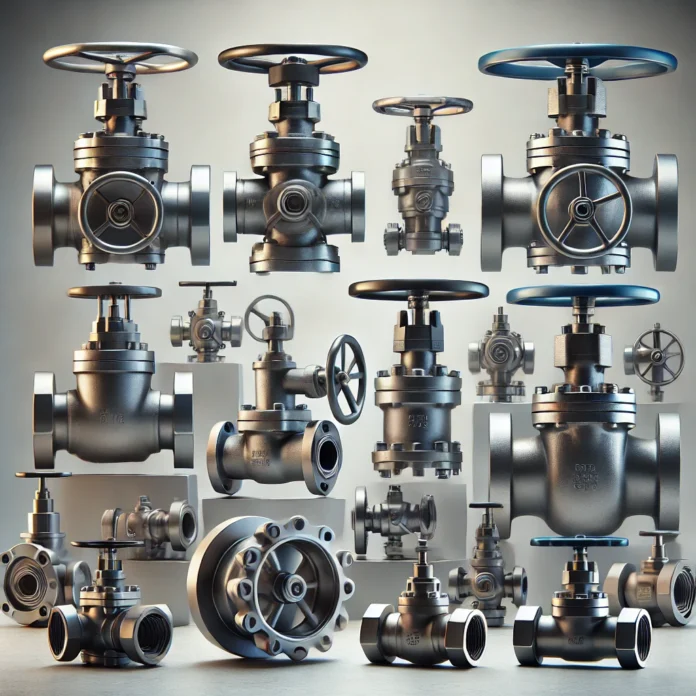

Valves serve as control points for fluids and gases in building systems. Below are the most common types of service valves, along with their functions and benefits:

1. Ball Valves

Ball valves are popular for their simplicity and reliability. They feature a rotating ball with a bore, controlled by a lever or handle.

Advantages:

- Easy to operate with a quarter-turn mechanism

- Durable and leak-proof when closed

- Suitable for high-pressure and high-temperature applications

Disadvantages:

- Limited control for throttling applications

2. Gate Valves

Gate valves operate by lifting a gate to allow fluid to flow through. These are commonly used in systems that require infrequent valve operation.

Advantages:

- Minimal flow resistance when fully open

- Ideal for straight-line fluid control

Disadvantages:

- Slower to operate compared to ball valves

- Prone to wear if used frequently

3. Globe Valves

Globe valves are designed for precise flow control and throttling. They regulate fluid by moving a disc against a stationary ring.

Advantages:

- Excellent for regulating flow rates

- Robust design for repeated use

Disadvantages:

- Higher pressure drop compared to other valve types

4. Butterfly Valves

Butterfly valves use a rotating disc to control flow. They are compact, lightweight, and cost-effective.

Advantages:

- Fast operation with quarter-turn control

- Compact and suitable for large systems

Disadvantages:

- Limited use in high-pressure systems

- Less effective in sealing compared to ball valves

5. Check Valves

Check valves are one-way valves that prevent backflow in a system, ensuring unidirectional flow.

Advantages:

- Essential for preventing contamination

- Automatic operation without manual intervention

Disadvantages:

- Can cause pressure loss in a system

Factors to Consider When Comparing Building Service Valves

Selecting the right valve for your project requires careful evaluation of several factors:

1. Application and System Requirements

- Flow Type: Is the valve needed for full flow, throttling, or shut-off purposes?

- Pressure and Temperature: Consider the operating pressure and temperature ranges of the system.

2. Material and Durability

Valves are made from various materials, including brass, stainless steel, and PVC. Each material has different properties regarding corrosion resistance, strength, and compatibility with fluids.

3. Size and Compatibility

Ensure the valve size matches the piping system’s diameter for optimal performance. Compatibility with existing systems is crucial for seamless integration.

4. Ease of Maintenance

Some valves require more maintenance than others. For instance, gate valves may need periodic cleaning to prevent debris buildup, while ball valves typically demand minimal upkeep.

5. Cost-Effectiveness

While initial costs are important, also consider long-term costs related to maintenance, replacement, and energy efficiency.

Comparison Chart: Key Features of Service Valves

| Valve Type | Best For | Pros | Cons |

|---|---|---|---|

| Ball Valve | Shut-off, high-pressure systems | Leak-proof, quick operation | Limited throttling capabilities |

| Gate Valve | Straight-line flow | Low resistance, cost-effective | Slow operation, maintenance needs |

| Globe Valve | Throttling control | Precision control, durability | Higher pressure drop |

| Butterfly Valve | Large flow systems | Compact, lightweight | Sealing limitations |

| Check Valve | Backflow prevention | Automatic operation, safe design | Pressure loss in system |

Key Takeaways

Selecting the right building service valve can significantly impact system efficiency, longevity, and safety. Consider the specific needs of your application, including fluid type, pressure, and operational preferences.

For large-scale systems, butterfly valves may offer a cost-effective solution. Meanwhile, ball valves are perfect for high-pressure, leak-proof systems. Globe valves are ideal for precision control, whereas check valves are essential for preventing backflow.

By understanding the pros and cons of each valve type, you can make an informed decision that meets both functional and budgetary requirements.

Take the Next Step with Ashworth

Ready to select the ideal building service valves for your project? At Ashworth, we offer a comprehensive range of high-quality valves tailored to meet your specific needs.

Explore our extensive product catalogue, gain expert advice, and ensure your system runs smoothly with the best solutions in the industry. Visit Ashworth’s website today and let us help you make the perfect choice for your building service system!

![21 Great Examples of PowerPoint Presentation Design [+ Templates] 21 Great Examples of PowerPoint Presentation Design [+ Templates]](https://apprenticeship-times.co.uk/wp-content/uploads/2019/10/powerpoint-design-examples-1-218x150.jpeg)